One of many realizations with our mechanic partner, ATS Group in France, is complex automation of dispatching systems, including ASRS feeding machines (Automated storage and retrieval system). We have another reference of 4 these ASRS machines, for example, in Michigan (USA).

We offer customized automation of ASRS, including WMS (Warehouse Management System) of the storage system and integration into the factory superior systems.

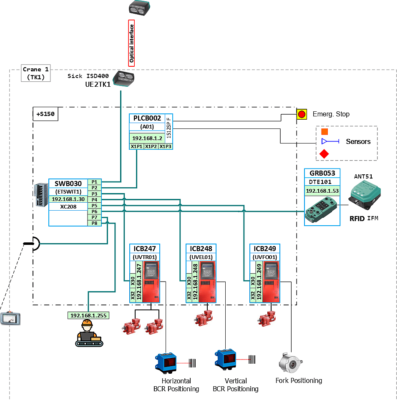

Basic applied automation means of the ASRS machine:

- Safety control system: SIMATIC ET 200SP (safety CPU 1512).

- Visualization: SIMATIC Comfort Panels, SIMATIC HMI KTP700F mobile panels.

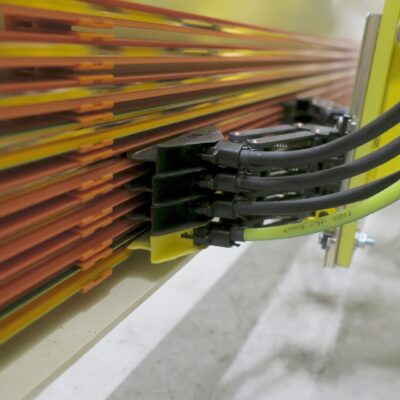

- Communication bus-bar: Profinet, IO-Link.

- Switch: SCALANCE XC208.

- Wire-free communication with a feeding machine: SICK ISD400-7212.

- BCR measurement of horizontal and vertical movements: SICK OLM100-1001.

- Frequency inverters for horizontal and vertical movements of the feeding machine, SEW Movidrive.

- RFID detection according to customer’s requirements (IFM, PEPPERL FUX, SIEMENS…).

Our delivery included:

- Technical solution, functional analysis.

- Creation of electric and technical documentation and layouts.

- Development of SW for PLC and HMI.

- Cooperation in preparing a communication protocol with a superior system.

- Manufacturing of switchboards and operator panels.

- Delivery of whole electric-wiring material.

- Electric mounting at the customer’s site

- Delivery of a WMS system (MES system IMPROVE iT!) custom-built in case of customer’s requirements.

- Adjusting and testing of functionality of the whole system.

- Operation and maintenance training, creation of manuals.

- After-selling assistance and remote SW service.

FAURECIA SOTEXO FRANCE – ASRS (AUTOMATED STORAGE AND RETRIEVAL SYSTEM)

FAURECIA SOTEXO FRANCE – ASRS (AUTOMATED STORAGE AND RETRIEVAL SYSTEM)