Complete electric equipment and control system of the production and conveyance line of KIA motor-car seats. Johnson Controls International was a very important customer for us, for which we realized – especially in Slovak Republic – several interesting projects.

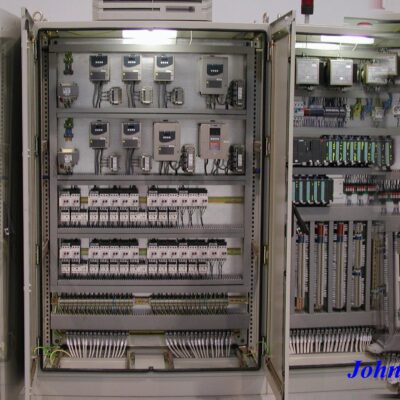

Basic applied automation means:

- Control system: 4x Simatic S7-300, Simatic S7-400 communication and data PLC.

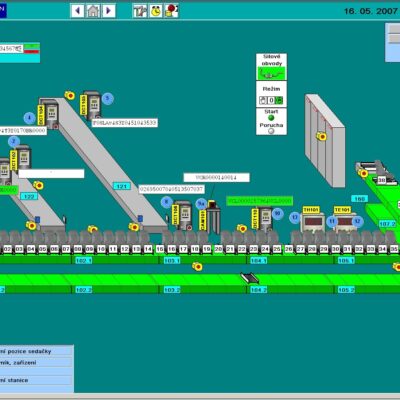

- Visualization: HMI/SCADA Genesis 32.

- Communication bus-bar: AS-i

- Circuit-breaker and inverter outputs for drivers, Altivar frequency inverters.

- Induction and optical sensors of the Sick and IFM conveying pallets.

- Sick fixed scanners

- RFID Balluff system.

Our delivery included:

- Technical solution, functional analysis.

- Creation of electric an technical documentation and layouts.

- Development of SW for PLC and HMI.

- Manufacturing of switchboards and operator panels.

- Delivery of whole electric-wiring material.

- Electric mounting at the customer’s site

- Implementation of a complex production tracking system and Poka-Yoke function.

- Data processing and their transfer to the TPDAS manufacturing system

- Adjusting and testing of functionality of the whole system.

- Operation and maintenance training, creation of manuals.

- After-selling assistance and service.

JOHNSON CONTROLS – PRODUCTION AND CONVEYANCE LINES

JOHNSON CONTROLS – PRODUCTION AND CONVEYANCE LINES