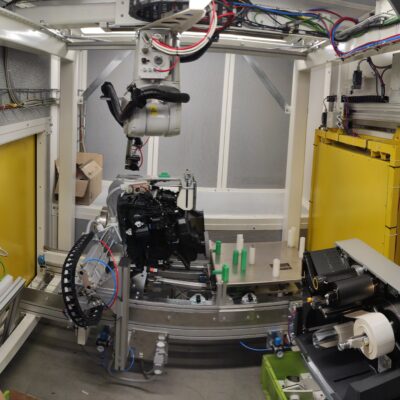

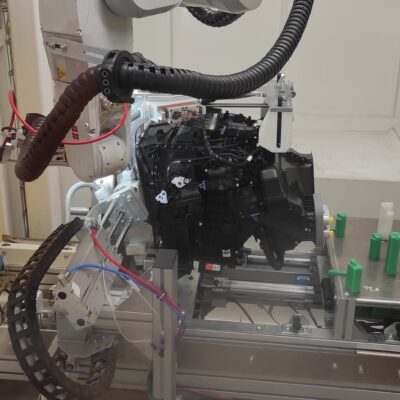

We realized automation for a series of production lines in the production plant in Valeo Rakovník. And in this case, we cooperated with our mechanical partner, TMT Chrudim. As an example of references, we can present one of our last realizations of a production line, Valeo MEB DS2. The line was fully putting into operation at the beginning of 2021. At the present time, we are working on a further project, this time it is delivery of automation for the Valeo MEB WS line.

Basic applied automation means:

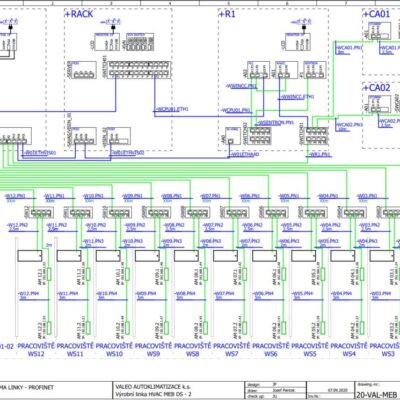

- Control system: 2 x SIMATIC S7-1500, distribution of I/O by means of SIMATIC ET200SP

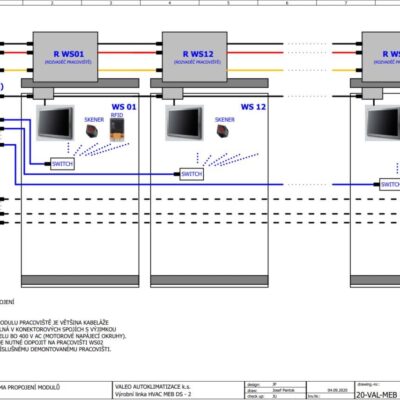

- Visualization: WinCC Advanced, UNIQ PC monitors.

- Communication bus-bars: Profinet, LIN bus, Ethernet TCP/IP.

- Circuit-breaker and inverter outputs for drivers.

- Induction and optical sensors.

- BCR identification – Keyence SR 751.

- RFID identification – IFM ANT513

- ABB IRB 1200 robot

- Dynamic camera system for the control of products, SMARTEK industrial vision, Vision Builder evaluating software.

- Printers of ID labels – Zbra.

- ODU automatic connecting (line -> pallet).

- Vaidiš connectors (pallet -> product).

Our delivery included:

- Fully user-programmable workplace in the whole line.

- Automation of the acoustic cabin for product testing.

- Automation of the cabin for video and electric product tests.

- Automatic label gluing.

- Automatic connecting in the cabins.

- Air flow-rate regulation.

- Technical solution, functional analysis.

- Creation of electric and technical documentation and layouts.

- Development of SW for PLC and HMI.

- Cooperation in solving communication with a superior system.

- Manufacturing of switchboards and operator panels.

- Delivery of whole electric-wiring material.

- Electric mounting at the customer’s site

- Adjusting and testing of functionality of the whole system.

- Operation and maintenance training, creation of manuals.

- Active after-selling assistance and service.

VALEO RAKOVNÍK – PRODUCTION LINES OF CAR AIR-CONDITIONING – STOP & GO

VALEO RAKOVNÍK – PRODUCTION LINES OF CAR AIR-CONDITIONING – STOP & GO